Chlorination Systems

Chlorination Systems are a very useful and practical way to handle a wide variety of water quality problems. Chlorine is an oxidant, meaning it can chemically change the molecular structure of many impurities. Oftentimes, the molecular structure of the newly formed impurity is easier to remove from the water supply. An excellent example of the oxidation process is the oxidation of iron. When chlorine in water interacts with dissolved iron, it alters it from a ferrous (fe+2) to a ferric (fe+3) state. The ferrous iron, sometimes called a clear water iron, cannot be easily filtered out of water; however, the ferric iron, sometimes called red water iron can be easily filtered out. Other impurities in the water are also affected by the oxidation principle of chlorine.

Additionally, chlorine is a powerful disinfectant, able to kill bacteria, viruses, and many other micro-organisms. This tactic has been used for over 100 years. Virtually all municipally treated water has chlorine added, often in a couple of different phases of the treatment process. Although very effective for bacteria and viruses, there are some micro-organisms such as cryptosporidium and giardia that are not effectively destroyed by chlorination.

Although chlorine does have some wonderful properties, it also has some negative characteristics. Chlorine will combine with certain organics in a water supply and create other organic compounds. One set of these organic compounds is known as Trihalomethanes, which have been linked with the occurrence of cancer. Another negative of chlorinated water (especially in high doses) is that the water is more aggressive towards piping, valves, faucets, and other plumbing fixtures. Finally, many consider chlorinated water to have an objectionable smell.

But there is good news: the three negative characteristics of chlorinated water are virtually eliminated on a GW Pumps & Purification chlorination system. Although these negative characteristics exist after the chlorinator and retention tank, the water is sent through a de-chlorination filter before going into the plumbing system. The GW de-chlorination filter has been designed to remove oxidized iron, trihalomethanes, chlorine, and many other impurities.

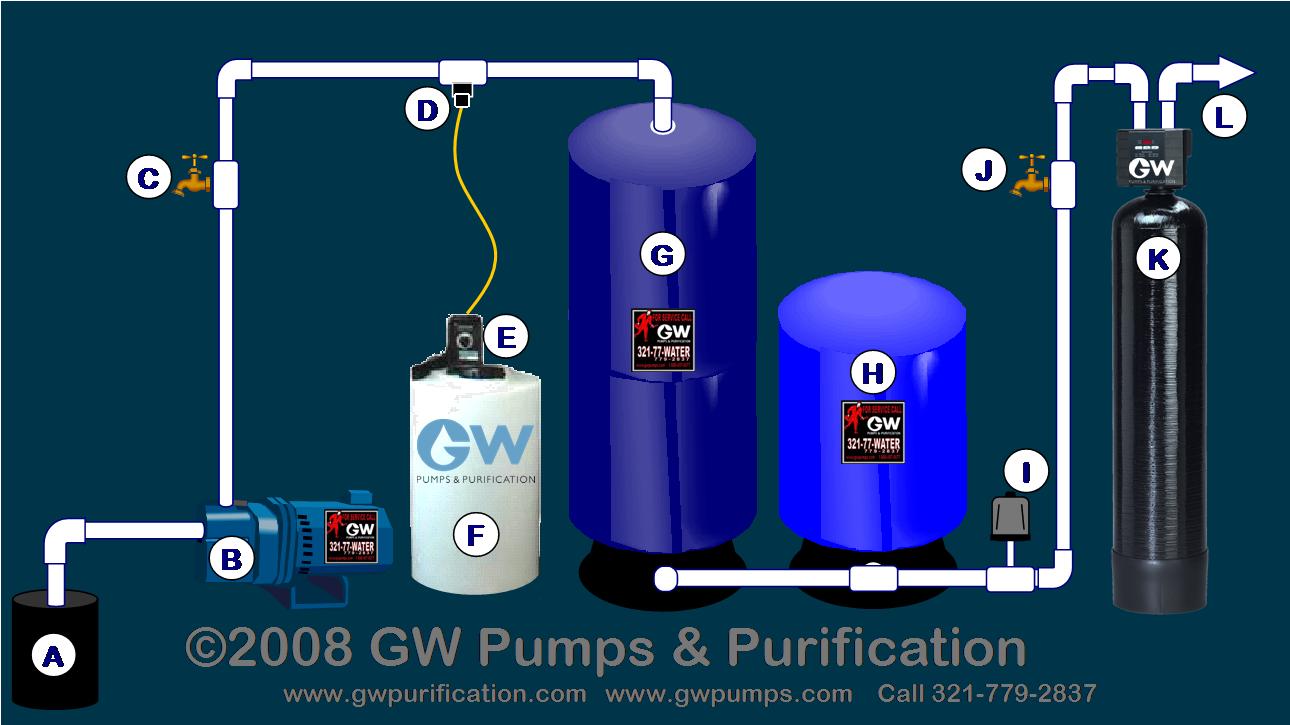

There are many components involved in a typical Chlorination system. The following is a listing of the components and a short description of the purpose of the component.

(A) Well – The water source

(B) Well Pump – The pump that provides water flow and pressure to the plumbing system.

(C) Sample Port – A hose bib or other valve that is installed to test the water quality. It is important to have a sample port prior to any water treatment equipment to test the untreated water at this point.

(D) Injector Fitting – This is a special fitting that has been designed to handle the corrosive chlorine and to prevent water from the pressurized pipe from flowing backwards into the chlorinator and/or solution tank.

(E) Chemical feed pump – This is the pump that creates high pressure and low flow. Depending on the model, some of these pumps, flow as low as 1/4 ounce per minute.

(F) Solution Tank – This tank is a non-pressurized tank that holds a mixture of liquid chlorine and purified water. In some cases straight liquid chlorine is used. Upon installation of your system, one of GW’s water experts will provide the proper mixture for your tank.

(G) Retention Tank or Contact Tank – This tank is designed to provide sufficient contact time, usually about 20 minutes, for the chlorine to properly serve its intended purpose. If you want to be able to continuously flow 5 gpm, you would need a 120 gallon retention tank. In no case should a system be installed without a retention tank.

(H) Pressure Tank – This tank uses compressed air in a sealed compartment to act as a buffer, storing the pressure created by the well pump. When filled(or at ~50 PSI), this tank should contain about 30% water and 70% compressed air. When nearing empty(or at ~30 PSI), this tank should contain only 2-3% water and 97-98% air. At ~30PSI the well pump should turn on and begin serving the needs of the home and also filling the pressure tank with water. The well pump will continue to run until the pressure reaches ~50 PSI. The experts at GW prefer to install the pressure tank after the retention tank to keep flow going past the injector fitting during normal system operation.

(I) Pressure Switch – Based upon the pressure being sensed, this switch turns on/off the well pump. Most Chlorination water systems also use the pressure switch to turn on/off the chemical feed pump at the same time the well pump turns on/off.

(J) Sample Port – A hose bib or other valve that is installed to test the water quality. It is important to have a sample port prior to the de-chlorination filter. Water at this point should contain the presence of free chlorine, If it does not, adjustments may be required to the chlorination system.

(K) De-chlorination filter – This filter removes the excess chlorine from the water supply, and also a wide variety of organics. The model shown in the image above includes an automatic back-washing controller. If iron or manganese is present in the well water, it is very important to install a back-washing de-chlorination filter.

(L) Water out – Water leaving this point is ready for either further treatment by a softener or other device and/or distribution into the plumbing system.

GW Pumps and Purification will gladly assist you with all your water pump and water treatment needs. In fact, “we make water easy!”

Verified Local Space Coast, Treasure Coast, and Central Florida Reviews